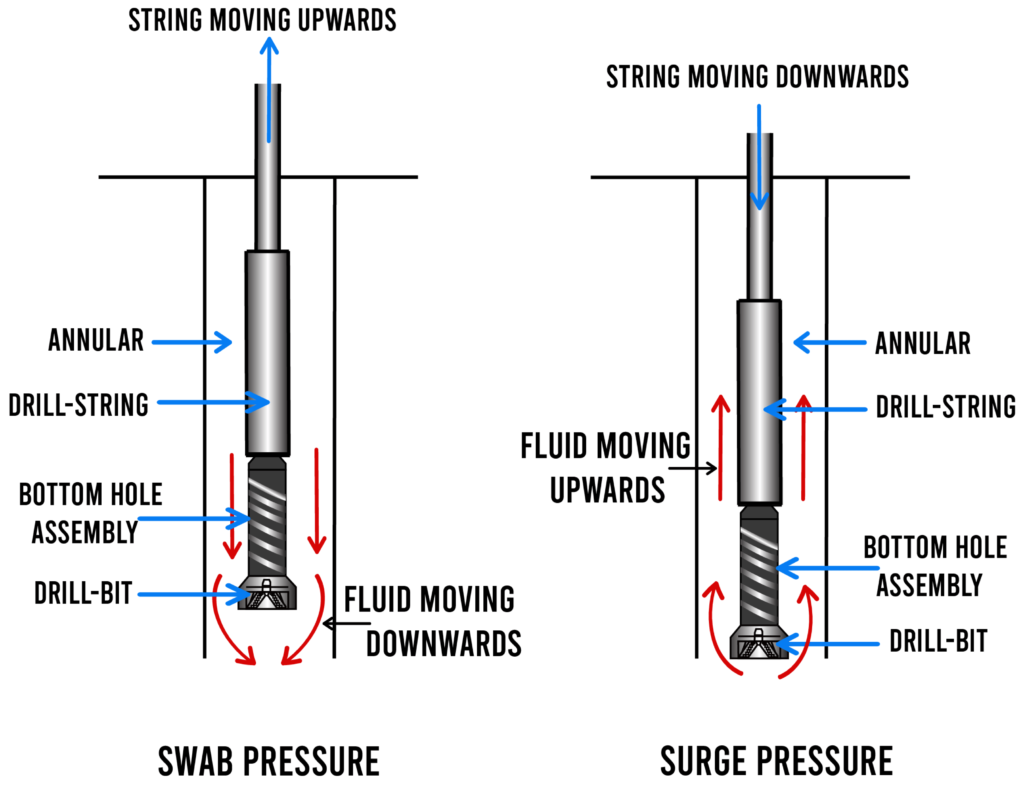

Movement of drill string down hole creates pressure surges in the borehole. These pressure surges could either add to the BHP (+ve surge) or reduce the BHP (-ve surge) depending upon whether the pipe is being lowered or pulled out of the well. The +ve pressure surges commonly known as ‘surge pressures’ if excessive can cause formation to fracture & lost circulation. The – ve surge pressure known as ‘swab pressure’ may reduce the BHP sufficient to permit the flow of formation fluid into the well.

Though accurate calculations of these swab & surge pressures are complicated, but since they are caused mainly by friction while ‘moving the drill string through mud, they are function of

a) Pipe speed

b) Mud properties such as viscosity & gel strength.

c) Annular clearance (pipe/hole diameter)

d) BHA length & size etc.

An acceptable rough estimate of swab pressure or decrease in BHP while pulling the pipe can be obtained by considering the friction effect values same as the circulating annular pressure losses. Or we can say that the minimum BHP while pulling pipe could be static BHP minus the circulating annular friction losses.

Though as the pipe is pulled up, some loss in BHP due to swabbing effect cannot be avoided, however, adequate measures should be taken to check that the pressure reduction should not exceed the overbalance pressure especially against permeable zones. Swabbing during trips could be detected by filling the trip sheets. If the swabbing remains undetected during initial stage, more and more formation fluid will reduce the BHP continuously and a stage will come when the well will start kicking and unloading the mud from the well.

Swab pressure can be very low but are compounded if :-

i) Mud viscosity and gel strength is high

ii) Pipe movement is rapid

iii) Wall cake is thick

iv) Annular clearance against BHA is small

v) Bit or stabilizer is balled up.

The formation permeability & pulling out through horizontal reservoir sections can compound the amount of formation fluid swabbed in.

High volume swabbing caused by piston effect of balled up bit, reamer or stabilizer associated with thick filter cake is clearly indicated at the surface when there is

- Excessive over pull, drag or torque

- No drop in mud level in the annulus

- Rise in mud level in the annulus when the drill string is being pulled.

- High rheology mud properties

- Drilling in reactive formation(Like Gumbo shales)

Such swabbing effects are rather obvious.

Drill pipe rubber also may swell if gas has been in the mud, and this too can increase the swabbing action. Therefore only drill pipe protectors which are highly resistant to swelling in the presence of hydrocarbons should be used. The swabbing tendency is maximum at the bit occurring proportionally alongside the whole drill string length. The greatest tendency to swab occurs as the bit is lifted off bottom, therefore a careful watch on the mud level in the annulus should be kept as the pipe is pulled. (The mud level should go down unless swabbing is taking place). A short trip may be necessary in critical situations.

The greatest tendency to swab occurs just as the bit leaves bottom. At this time the most careful checks need to be made to determine if formation fluids are being swabbed into the hole.

While trip out monitor trip sheet carefully and if well takes less volume than pulled out volume, it indicates swabbing and some influx has been sucked into the well. Make a flow check and if flow check is positive, immediately shut in the well and then plan for strip-in. If flow check is negative, the pipe must be run back to bottom monitoring the return rate on trip sheet. After reaching bottom, the influx is to be circulated out with the same mud which was used at the time of drilling.

The best method is based on checking the volume of mud needed to replace the volume of steel removed. Pipe displacement can be read from tables or calculated by the formula:

Displacement (bbl./ft) = Weight per ft.(lb/ft) / 2730

The amount of mud used to fill the hole can be measured by counting the pump strokes needed to fill the well or by using a trip tank. A trip tank allows the accurate measurement of relatively small volumes of mud. Volume measurements in the mud pits are generally too inaccurate to detect the small changes in volumes required. Companies use trip books to record the volumes used on each hole fill and the running sum. The recorded volumes can be compared at intervals with records of previous trips.

Keeping the hole full is most critical when drill collars are pulled from the well, because the collars have more volume than drill pipe, the mud level will fall four to five times as far. To prevent a reduction in well pressure greater than when pulling drill pipe , the hole should be filled every stand when pulling collars.

Procedure to be followed:

- Monitor hole fill up on trips

- Limit pipe pulling and running speeds

- Add trip margin

- If swabbing is severe , consider pumping out of hole

- Trip sheet should be used to compare actual and calculated volume displaced.

- Trip tank must be accurately calibrated and monitored by crew members

- Plan the trip –have a set schedule of stands pulled between fill ups, have a sound

procedure for refilling trip tank and transferring surface mud volumes.

You can learn more about oil well drilling at http://oilwellconsultancy.com

Disclaimer: General reading purpose only.