Drilling Fluids

A drilling fluid is any fluid which is circulated through a well in order to remove cuttings from a wellbore. We will discuss fluids which have water or oil as their continuous phase.

A drilling fluid must fulfill many functions in order for a well to be drilled successfully, safely, and economically. The most important functions are:

- Remove drilled cuttings from under the bit

- Carry those cuttings out of the hole

- Suspend cuttings in the fluid when circulation is stopped

- Release cuttings when processed by surface equipment

- Allow cuttings to settle out at the surface

- Provide enough hydrostatic pressure to balance formation pore pressures

- Prevent the bore hole from collapsing or caving in

- Protect producing formations from damage which could impair production

- Clean, cool, and lubricate the drill bit

Occasionally, these functions require the drilling fluid to act in conflicting ways. It can be seen that items #1-3 are best served if the drilling fluid has a high viscosity, whereas items #4-5 are best accomplished with a low viscosity. Items #6 & 8 are often mutually exclusive because drilled solids will tend to pack into the pore spaces of a producing formation.

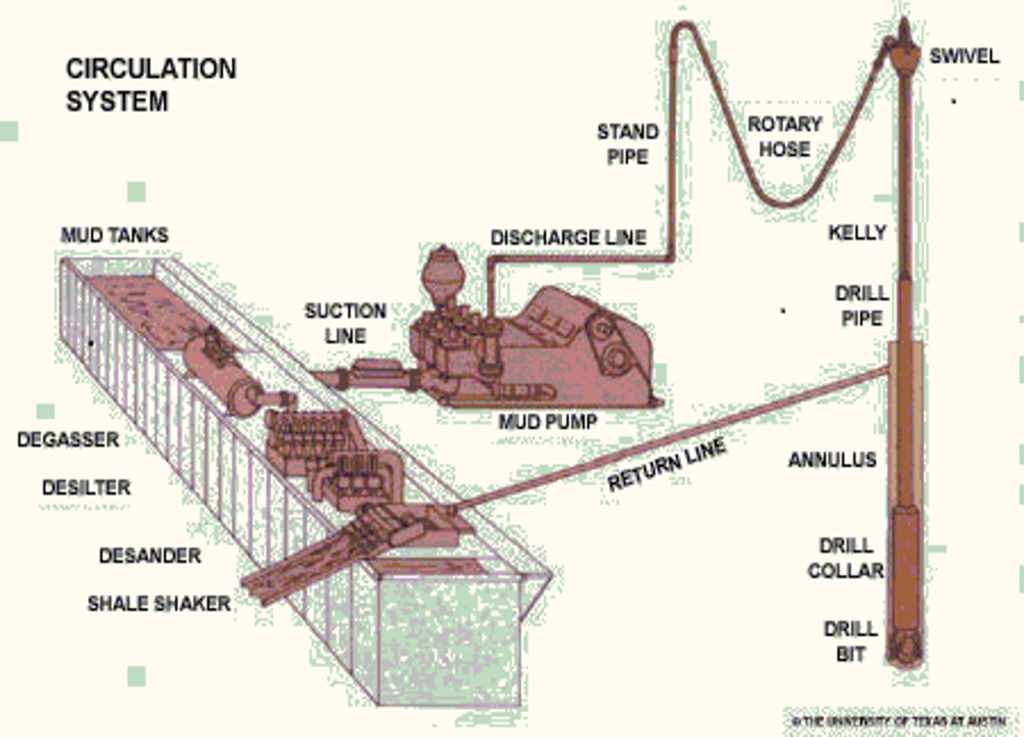

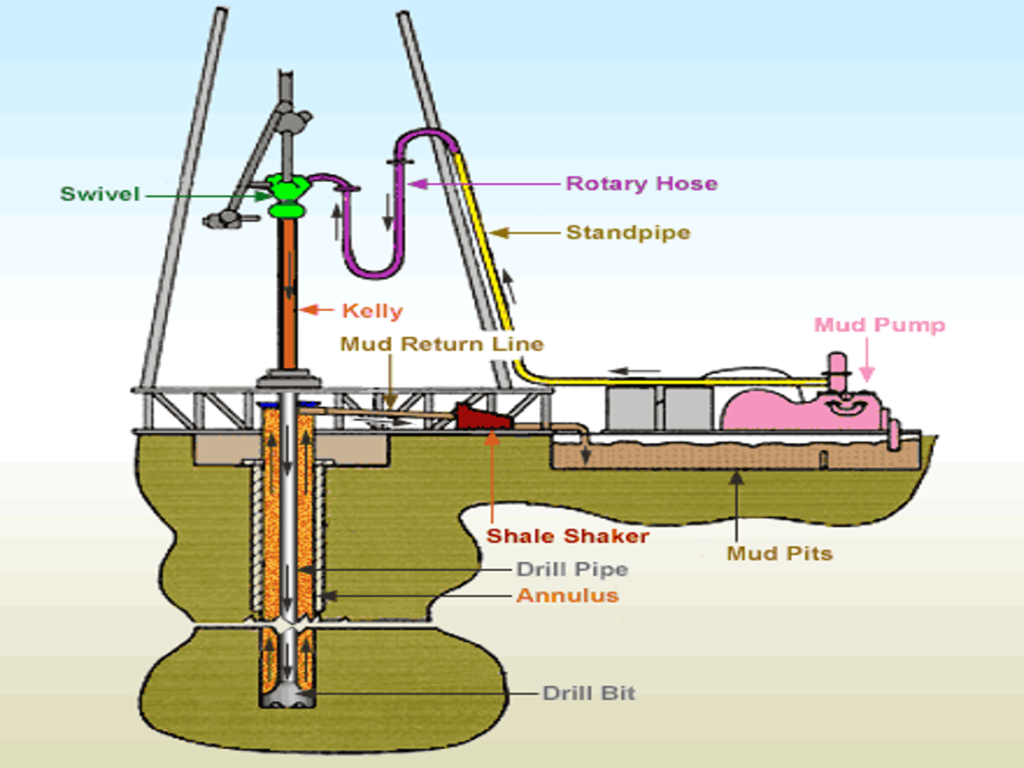

Circulation System.

Make-up of a Drilling Fluid

In its most basic form a drilling fluid is composed of a liquid (either water or oil) and some sort of viscosifying agent. If nothing else is added, whenever the hydrostatic pressure is greater than the formation pore pressure (and the formation is porous and permeable) a portion of the fluid will be flushed into the formation. Since excessive filtrate can cause borehole problems, some sort of filtration control additive is generally added. In order to provide enough hydrostatic pressure to balance abnormal pore pressures, the density of the drilling fluid is increased by adding a weight material (generally barite).

In summary, a drilling fluid consists of: The Base Liquid

- Water – fresh or saline

- Oil – diesel or crude

- Mineral Oil or other synthetic fluids Dispersed Solids

• Colloidal particles, which are suspended particles of various sizes

Dissolved Solids

• Usually salts, and their effects on colloids most is important

All drilling fluids have essentially the same properties, only the magnitude varies. These properties include density, viscosity, gel strength, filter cake, water loss, and electrical resistance.

Normal Drilling Fluids

Though this type of drilling fluid is easy to describe, it is hard to define and even more difficult to find. In the field, a normal fluid generally means there is little effort expended to control the range of properties. As such, it is simple to make and control. General rules include:

- It is used where no unexpected conditions occur

- The mud will stabilize, so its properties are in the range required to control hole conditions

- The chief problem is viscosity control

Formations usually drilled with this type of mud are shales and sands. Since viscosity is the major problem, the amount and condition of the colloidal clay is important. To do this, two general types of treatment are used:

- Water soluble polyphosphates

(a) they reduce viscosity

(b) can be used alone or with tannins

(c) if filter cake and filtration control is required – add colloidal clay to system

2. Caustic Soda and Tannins

(a) they also reduce viscosity

(b) used under more severe conditions than phosphate treatment

The upper portions of most wells can use “normal” muds

- Care must be taken not to add chemicals which may hinder the making of special muds later on

- Native clays used to make the mud are usually adequate

Special Drilling Fluids

These drilling fluids are made to combat particular abnormal hole conditions like shale or to accomplish specific objectives. These are:

- Special Objectives

(a) faster penetration rates

(b) greater protection to producing zones - Abnormal Hole Conditions (a) long salt sections (b) high formation pressures

Lime Base Muds

1. Water based Mud

2. Treated with large amounts of caustic soda, quebracho, and lime. Added in that order

3. Ratio of 2 lb caustic soda, 1.5 lb quebracho and 5 lb lime per 1 barrel of mud

4. Will go through a highly viscous stage, but will become stable at a low viscosity

5. Good points

(a) can tolerate large amounts of contaminating salts

(b) remains fluid when solids content gets high

6. Weakness – it has a tendency to solidify when subjected to high bottom-hole temperatures

Lime-Treated Muds

- Similar to lime based mud – differ only in degree

- A compromise attempt at overcoming the high temperature gelation problem (a) use less lime than lime-base mud

(b) not nearly so resistant to salt contamination

Emulsion Muds – Oil in Water

- Oil can be added to any of the normal or special muds with good results

- No special properties necessary

- Natural or special emulsifying agents hold oil in tight suspension after mixing

- Oils used are: (a) Crude oils (b) Diesel (c) any oil with an API gravity between 25 and 50

- Oil content in mud may be 1% to 40%

- Advantages are: (a) very stable properties

(b) easily maintained

(c) low filtration and thin filter cake (d) faster penetration rates

(e) reduces down-hole friction - Major objection is that the oil in the mud may mask any oil from the formations

Inhibited Muds

1. Muds with inhibited filtrates

2. Large amounts of dissolved salts added to the mud

3. High pH usually necessary for best results

4. Designed to reduce the amount of formation swelling caused by filtrate – inhibit clay hydration

5. Disadvantages

(a) need specialized electric logs

(b) requires much special attention

(c) low mud weights cannot be maintained without oil

(d) hard to increase viscosity

(e) salt destroys natural filter cake building properties of clays

Gypsum Base Muds

- A specialized inhibited mud

(a) contained large amounts of calcium sulfate (b) add 2 lb/bbl gypsum to mud system

(c) filtration controlled by organic colloids - Advantages

(a) mud is stable (b) economical to maintain

(c) filtrate does not hydrate clays (d) high gel strength - Disadvantages

(a) fine abrasives remain in mud (b) retains gas in mud

Oil Based Muds

1. Oil instead of water used as the dispersant

2. Additives must be oil soluble

3. Generally pre-mixed and taken to the wellsite

4. To increase aniline value, blown asphalt and unslaked lime may be added

5. Advantages

(a) will not hydrate clays

(b) good lubricating properties (c) normally higher drill rates

6. Disadvantages

(a) expensive

(b) dirty to work with

(c) requires special electric logs

(d) viscosity varies with temperature

Inverted Emulsions

- Water in oil emulsion. Oil largest component, then water added. Order of addition is important

- Have some of the advantages of oil muds, but cheaper. Somewhat less stable

Salt Water Muds

- Can be used either completely or partly saturated

- Weight can vary up to 10 lb/gal when saturated

- No filter cake building properties, easily lost to porous formations

Silicate Muds

- Composed of sodium silicate and saturated salt water

- Has a pickling effect on shales which prevents heaving or sloughing

- Will be 12 lb/gal or higher

- Corrosive, expensive and gives poor electric log results

Low Solids Muds

1.Keeps amounts of clays in the mud at a minimum, which promotes faster and safer drilling

2.Three ways to remove solids from mud

(a) water dilution

(b) centrifuging

(c) circulate through large surface area pits

3.When clays are removed, a minimum of viscosity control chemicals are needed

4. When viscosity and gel strength become too low, clay solids are replaced by organic or suspended material – polymers

5.Other advantages (a) good for drilling with large pumps and high mud volumes (b) always give faster drilling

6.Problems (a) excessive dilution a problem (b) can become expensive

Drilling Fluid Classification Systems

Non-Dispersed System

This mud system consists of spud muds, “natural” muds, and other lightly treated systems. Generally used in the shallower portions of a well.

Dispersed Mud Systems

These mud systems are “dispersed” with deflocculants and filtrate reducers. Normally used on deeper wells or where problems with viscosity occur. The main dispersed mud is a “lignosulfonate” system, though other products are used. Lignite and other chemicals are added to maintain specific mud properties.

Calcium-Treated Mud Systems

This mud system uses calcium and magnesium to inhibit the hydration of formation clays/shales. Hydrated lime, gypsum and calcium chloride are the main components of this type of system.

Polymer Mud Systems

Polymers are long-chained, high molecular-weight compounds, which are used to increase the viscosity, flocculate clays, reduce filtrate and stabilize the borehole. Bio-polymers and cross-linked polymers, which have good shear-thinning properties, are also used.

Low Solids Mud System

This type of mud system controls the solids content and type. Total solids should not be higher than 6% to 10%. Clay content should not be greater than 3%. Drilled solids to bentonite ratio should be less than 2:1.

Saturated Salt Mud Systems

A saturated salt system will have a chloride content of 189,000 ppm. In saltwater systems, the chloride content can range from 6,000 to 189,000 ppm. Those at the lower end are normally called “seawater” systems.

These muds can be prepared with fresh or salt water, then sodium chloride or other salts (potassium, etc.) are added. Attapulgite clay, CMC or starch is added to maintain viscosity.

Oil-Based Mud Systems

There are two types of systems: 1) invert emulsion, where water is the dispersed phase and oil the continuous phase (water-in-oil mud), and 2) emulsion muds, where oil is the dispersed phase and water is the continuous phase (oil-in-water mud). Emulsifiers are added to control the rheological properties (water increases viscosity, oil decreases viscosity).

Air, Mist, Foam-Based Mud Systems

These “lower than hydrostatic pressure” systems are of four types: 1) dry air or gas is injected into the borehole to remove cuttings and can be used until appreciable amounts of water are encountered, 2) mist drilling is then used, which involves injecting a foaming agent into the air stream, 3) foam drilling is used when large amounts of water is encountered, which uses chemical detergents and polymers to form the foam, and 4) aerated fluids is a mud system injected with air to reduce the hydrostatic pressure.

Workover Mud Systems

Also called completion fluids, these are specialized systems designed to 1) minimize formation damage, 2) be compatible with acidizing and fracturing fluids, and 3) reduce clay/shale hydration. They are usually highly treated brines and blended salt fluids.

Drilling Fluid Additives

Many substances, both reactive and inert, are added to drilling fluids to perform specialized functions. The most common functions are:

1. Alkalinity and pH Control

Designed to control the degree of acidity or alkalinity of the drilling fluid. Most common are lime, caustic soda and bicarbonate of soda.

2. Bactericides

Used to reduce the bacteria count. Paraformaldehyde, caustic soda, lime and starch preservatives are the most common.

3. Calcium Reducers

These are used to prevent, reduce and overcome the contamination effects of calcium sulfates (anhydrite and gypsum). The most common are caustic soda, soda ash, bicarbonate of soda and certain polyphosphates.

4. Corrosion Inhibitors

Used to control the effects of oxygen and hydrogen sulfide corrosion. Hydrated lime and amine salts are often added to check this type of corrosion. Oil-based muds have excellent corrosion inhibition properties.

5. Defoamers

These are used to reduce the foaming action in salt and saturated saltwater mud systems, by reducing the surface tension.

6. Emulsifiers

Added to a mud system to create a homogeneous mixture of two liquids (oil and water). The most common are modified lignosulfonates, fatty acids and amine derivatives.

7. Filtrate Reducers

These are used to reduce the amount of water lost to the formations. The most common are bentonite clays, CMC (sodium carboxymethylcellulose) and pre-gelatinized starch.

8. Flocculants

These are used to cause the colloidal particles in suspension to form into bunches, causing solids to settle out. The most common are salt, hydrated lime, gypsum and sodium tetraphosphates.

9. Foaming Agents

Most commonly used in air drilling operations. They act as surfactants, to foam in the presence of water.

10. Lost Circulation Materials

These inert solids are used to plug large openings in the formations, to prevent the loss of whole drilling fluid. Nut plug (nut shells), and mica flakes are commonly used.

11. Lubricants

These are used to reduce torque at the bit by reducing the coefficient of friction. Certain oils and soaps are commonly used.

12. Pipe-Freeing Agents

Used as spotting fluids in areas of stuck pipe to reduce friction, increase lubricity and inhibit formation hydration. Commonly used are oils, detergents, surfactants and soaps.

13. Shale-Control Inhibitors

These are used to control the hydration, caving and disintegration of clay/ shale formations. Commonly used are gypsum, sodium silicate and calcium lignosulfonates.

14. Surfactants

These are used to reduce the interfacial tension between contacting surfaces (oil/water, water/solids, water/air, etc.).

15. Weighting Agents

Used to provide a weighted fluid higher than the fluids specific gravity. Materials are barite, hematite, calcium carbonate and galena.

Chemicals & their Functions:

1. Cake Forming Material: Bentonite Powder, MCC

2.Shale Stablizers : Sulphonated Asphalt, Polyol

3.Corrsion Inhibitor: Sodium Sulphite

4. Shale Inhibitors: KCL, PHPA

5.Weighting Materials: Barytes, Lime Stone Powder, Hematite

6. Filtration Controllers: PGS (Pre Gelatinized Starch) , CMC-LVG (Carboxy Methyl Cellulose), PAC-LVG (Poly Anionic Cellulose) PAC-RG

7. Lubricants: Linseed Oil, EP Lube, Polyol

8. Thinners & Dispersants: Lignite Powder, Resinated Lignite, Chrome Lignite, K+ Lignite

9. pH Controllers: NaOH, KOH, Soda Ash

10.Deflocculants : CFD, HT deflocculant

11.Lost Circulation Materials : MCC, Mica, Saw Dust, Rice Husk

Mud Policy Case study.

•PHASE-I (17 ½” / 12 ¼” Hole) : Bentonite Gel , S.G.:1.05-1.08*

•PHASE-II (12 ¼”/ 8 ½” Hole) : CMC-CFD Mud/ Lightly treated mud/, Gel Polymer S.G.:1.08-1.12*

•PHASE-III (8 ½”) : Highly treated mud/Gel Polymer/KCl Polymer/NDDF , S.G.:1.12-1.40*

1. Bentonite Gel:

Bentonite : 6-7%

Caustic : 0.1%

DD : 0.1%

Soda Ash : 0.1%

CMC-CFD Mud:

Bentonite : 5-6%

Caustic : 0.1%

CL : 1.0%

RL : 2.0%

CMC :1.0-2%

DD* : 0.5%

SA : 2.0%

Baryte : APR

KCl Polymer:

PHBS : 2-3%

Soda Ash : 0.1%

PHPA : 0.3-0.5%

KOH : 0.1%

KCl : 5-6%

PAC-LVG : 1-2%

PAC-RG : 0.5%

XCP : 0.4%

DD* : 0.5%

SA : 2.0-3.0%

NIFA : 2-3%

MCC : 5-6%

Polyol Gd-I : 3-4%

Biocide : 0.1%

Barytes : APR

You can learn more about Oil Well Drilling at http://oilwellconsultancy.com

Disclaimer: The information provided on this educational blog is for general informational purposes only.